Have you been infected with COVID-19 for a second time recently?

At the turn of summer and autumn, the temperature is changeable, and there is a large flow of people and intensive activities. The risk of the spread of respiratory diseases such as COVID-19 and influenza is superimposed. In the post-epidemic era, environments such as elevators and offices have greater risks of transmission. Therefore, improving the antibacterial performance of antibacterial materials in such environments is extremely important in the context of the post-epidemic era.

According to demand, in order to improve the antibacterial performance of plastic products in public places and increase investment in production, antibacterial additives with high efficiency and simple methods must be selected. Antibacterial masterbatch can accomplish this mission.

Introduction to antibacterial masterbatch

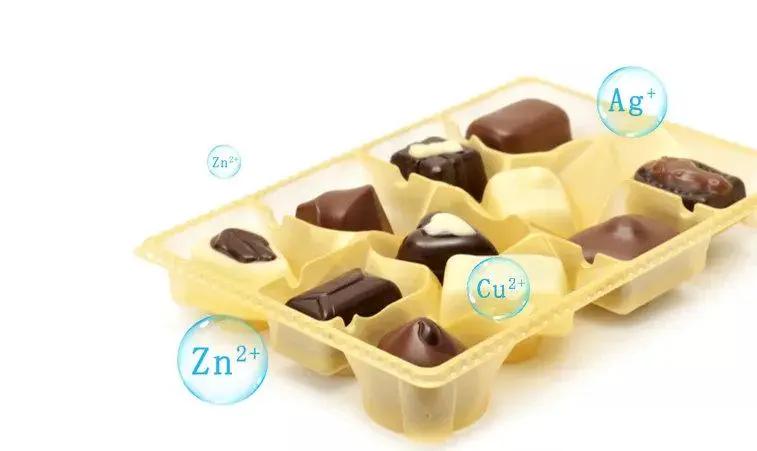

Antibacterial masterbatch is an additive that can be added to plastics, rubber, textiles and other materials to inhibit the growth of bacteria and fungi. It can be used in medical, food packaging, household products and other fields. So, how does it work as an antibacterial?

Staphylococcus aureus on ordinary plastic and antibacterial plastic surfaces

Antibacterial masterbatch is usually composed of metal ions such as silver, copper, zinc, etc. These ions can destroy the cell walls and cell membranes of bacteria, thereby killing them. This is why when we use products containing antibacterial masterbatch in our daily life, we can more effectively prevent the growth of bacteria and fungi.

Advantages of antibacterial masterbatch

Antibacterial masterbatch is classified differently according to the addition of antibacterial agents. According to the classification of antibacterial agents, antibacterial masterbatch is also divided into organic antibacterial masterbatch, inorganic antibacterial masterbatch and natural antibacterial masterbatch.

![/uploads/image/2023/12/20/6DDY]4RPG_~PSH~CK{GZ@B2.png 6DDY]4RPG_~PSH~CK{GZ@B2.png](/storage/uploads/image/2023/12/20/6DDY]4RPG_~PSH~CK{GZ@B2.png)

The addition of antibacterial masterbatch has a critical impact on the final performance of plastics. Research has found that adding antibacterial masterbatch has almost no impact on the mechanical and physical properties of plastics. This is mainly because the matrix of antibacterial masterbatch is usually the same as the matrix of plastic or has high compatibility, so the addition of antibacterial masterbatch can It adapts well to the plastic matrix and will not cause plastic deterioration.

Antibacterial Masterbatch Application

In the medical field, the application of antibacterial masterbatch is particularly important. Medical devices, surgical gowns, masks, etc. can be added with antibacterial masterbatch to reduce the risk of hospital infections.

Antibacterial dressing

In the field of food packaging, antibacterial masterbatch can also prevent food from being contaminated by bacteria, thereby ensuring food safety.

Antibacterial food packaging

At present, antibacterial plastics have been used on a large scale in the automotive industry, and more and more antibacterial plastics will be used in the interiors of high-end cars, such as steering wheels, handles, seat cushions, etc.

Antimicrobial plastics could be used in many parts of cars

In addition, antibacterial plastics are also widely used in household appliances, building materials, daily necessities and other fields. So how should plastic products choose an antibacterial masterbatch with excellent performance?

Honye antifungal and antibacterial masterbatch

HY-F320: Copper-based antibacterial, adding as little as 2% can achieve an effective sterilization rate of more than 99%, with a slight blue phase.

HY-F330: Silver and zinc are antibacterial and highly effective. Adding 3% can reach more than 99%. The sterilization effect can meet the production requirements of fine-denier chemical fibers.

HY-F360: Organic antibacterial, certified by EPA and BPR, highly effective in antibacterial and mildew prevention.

Honye has designed a variety of antibacterial masterbatch according to the needs of different antibacterial plastics. The effective sterilization rate can reach more than 99%. It has no precipitation, no clogging, and is super resistant to yellowing. It meets the dual needs of antibacterial and mildew prevention and is hygienic, more secure.

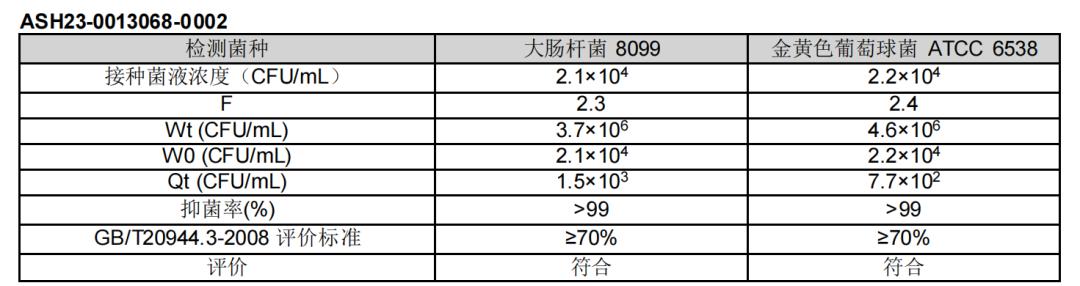

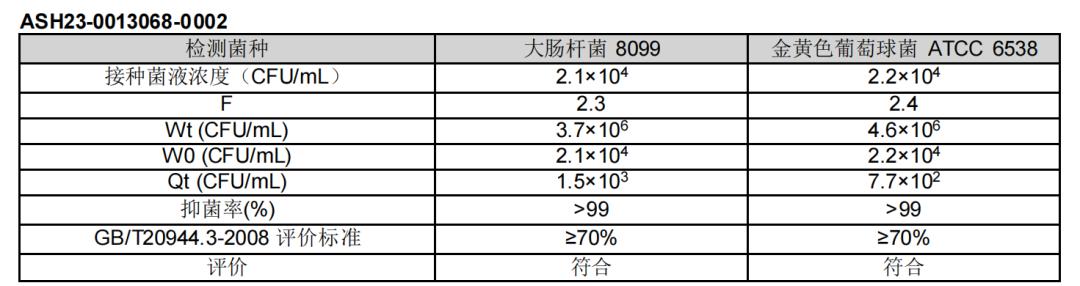

HY-F320 antibacterial performance test

HY-F330 antibacterial performance test

In the post-epidemic era after the COVID-19 epidemic spread across the world, the rigid demand for healthy antibacterial products has increased rapidly, and the application of antibacterial plastics in daily life has become an important way to differentiate plastic products. If you need samples or test reports, please contact our sales representative!

English

English

![/uploads/image/2023/12/20/6DDY]4RPG_~PSH~CK{GZ@B2.png 6DDY]4RPG_~PSH~CK{GZ@B2.png](/storage/uploads/image/2023/12/20/6DDY]4RPG_~PSH~CK{GZ@B2.png)